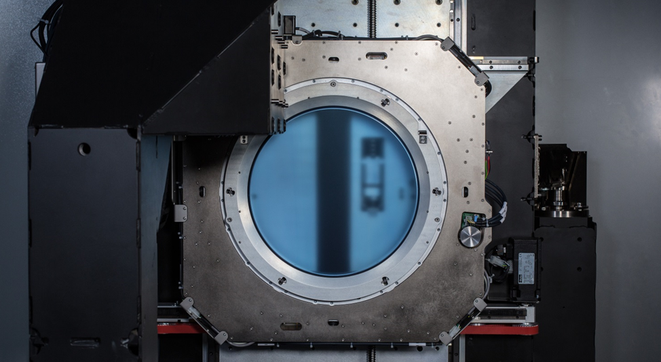

Pilot 2: 12'' Wafer Stage

Nexperia is a global leader in the manufacturing of semiconductor components. Nexperia focuses on

efficient production of consistently reliable semiconductor components in high volumes. Semiconductor manufacturing and assembly equipment is often designed and developed in-house.

A new wafer stage is being developed for Nexperia’s ADAT3 pick-and-place platform. A wafer stage is one of the most critical test cases of a mechatronic system in semiconductor manufacturing and

assembly equipment. Typical pick-and-place processes in semiconductor assembly require a very accurate alignment of the semiconductor component and pick-up tool at a fixed pick-up position. The

industrial environment of the semiconductor assembly operation puts demanding requirements on servo motion performance because solutions must meet challenging technical requirements regarding

accuracy and throughput, robustness and affordability.

The system architecture of the ADAT3 wafer stage is classical for cost reasons, using moving modules mounted on a rigid machine frame. The frame serves as metrological reference as well as the

force frame absorbing the reaction forces, which leads to crosstalk between servo axes. Careful dynamical design is required to assure individual axes are performing within tolerance budget.

Motion control of the wafer stage must therefore take internal dynamics of the stage and dynamics from the surroundings into account in order to reach micrometer accuracy and repeatability.

Furthermore, motion control features like MIMO control and well-tuned feedforward controllers are necessary to achieve the required performance.

Several technologies will be tested on the wafer stage pilot system during the I-MECH project to increase performance of the wafer stage even further. Adaptive control strategies, to cope with

machine-to-machine variations and time-dependent behavior like friction, motor constants, wear, temperature fluctuations, in-line automatic servo tuning, condition monitoring and advanced

model-based methods for the design, control and condition monitoring purposes will be among the I-MECH technologies to be evaluated on Nexperia’s wafer stage.